1. The Importance of Cleanroom Validation in Electronics

In the electronics and semiconductor industry, the cleanroom acts as a “shield” to protect products from risks caused by dust, microorganisms, and electrostatic discharge (ESD). To ensure that this environment consistently meets standards, cleanroom validation is a mandatory step in the operation of any factory.

The role of validation in product quality

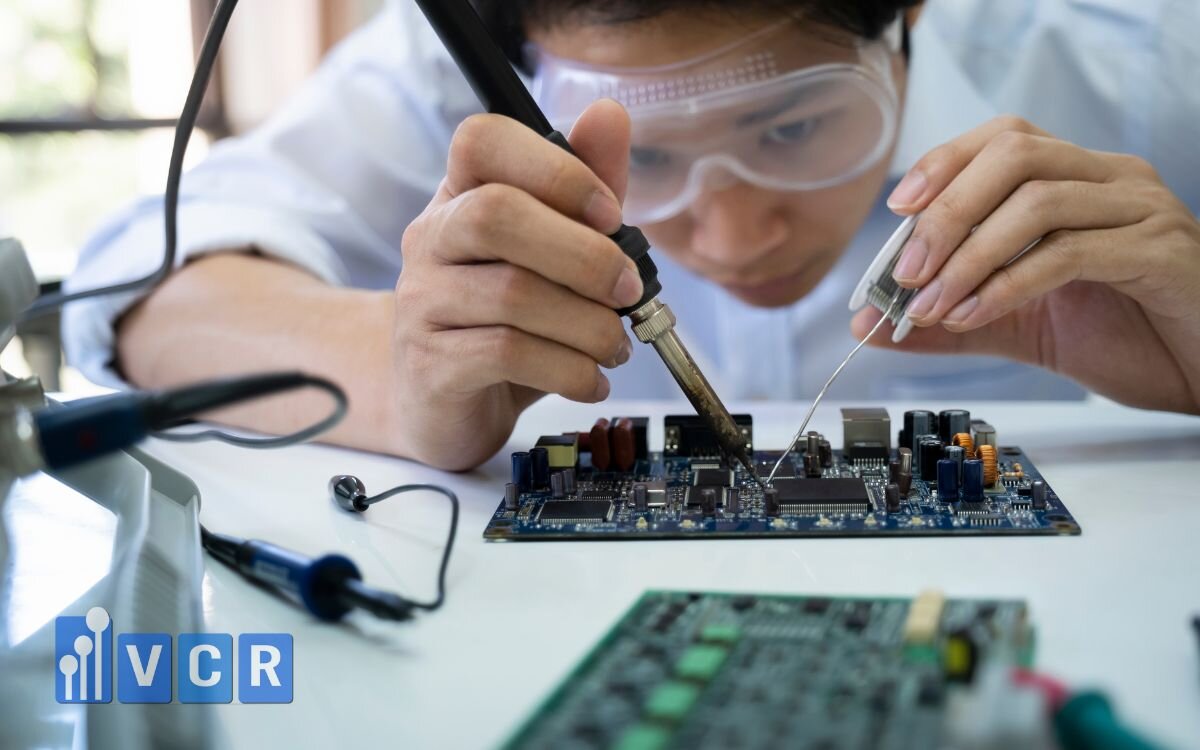

- Protecting electronic components and printed circuit boards (PCB): even a dust particle at the micrometer level can cause circuit failures, short circuits, or reduce product lifespan.

- Preventing ESD (Electrostatic Discharge) incidents: validation helps detect early malfunctions in the ESD control system, avoiding damage to chips and ICs.

- Ensuring stable production: once the cleanroom is validated to standard, defect rates are reduced, and productivity and profit significantly increase.

Commonly applied validation standards

- ISO 14644: the most widely used international standard for classifying cleanliness levels and airborne particle measurement.

- IPC (Association Connecting Electronics Industries): defines technical requirements for printed circuit boards and electronic products.

- IEST (Institute of Environmental Sciences and Technology): provides detailed guidance on HEPA/ULPA filter testing, ESD control, and other environmental factors.

Consequences of incorrect or omitted validation

- Increased contamination risk: leading to mass defects in semiconductor and electronic component manufacturing.

- Uncontrolled ESD: causing irreparable damage to microprocessors.

- Economic losses: maintenance, replacement, and product recall costs may far exceed the investment required for proper validation.

2. Common Errors in Cleanroom Validation for Electronics

In practice, many electronics factories encounter errors during cleanroom validation that directly affect the accuracy of results. Below are the most common issues to watch out for:

Errors in airborne particle measurement

- Non-compliance with ISO 14644: sampling is performed incorrectly (time, flow rate, sampling points), making results unrepresentative of actual conditions.

- Unrepresentative particle counter placement: measuring only in low-activity areas while ignoring sensitive zones (SMT lines, soldering, packaging), leading to skewed data.

Insufficient ESD (Electrostatic Discharge) control

- Skipping checks on ESD-protective equipment: failing to measure resistance of vinyl flooring, ESD chairs, and wrist straps on a regular basis.

- Lack of ESD equipment calibration: resulting in inaccurate readings, increasing the risk of chip and IC failures during production.

Improper differential pressure control

- Incorrect differential pressure gauge installation: gauges placed in non-critical or hard-to-monitor areas produce inaccurate data.

- Failure to maintain minimum differential pressure (10-15 Pa): between cleanroom classifications, allowing cross-contamination from dirtier to cleaner areas.

Errors in HEPA/ULPA filter validation

- Incomplete DOP/PAO testing: skipping filter efficiency tests increases the risk of undetected particle leakage.

- Incorrect leak scan technique: improper scanning misses gaps and leaks in the filter frame.

Lack of standardized documentation and checklists

- Absence of SOP (Standard Operating Procedure): validation is carried out inconsistently without unified guidelines.

- Reports lacking legal compliance: missing QA/QC signatures or standardized forms, making traceability difficult in case of incidents.

3. Solutions and Preventive Measures

To minimize errors during cleanroom validation in electronics, companies need to implement a combination of measures. Below are the most important ones:

Develop a validation checklist according to ISO 14644

- Create a standardized validation criteria set, including particle count, differential pressure, ESD, filtration system, temperature, and humidity.

- A checklist helps synchronize procedures across validation sessions and ensures no critical steps are skipped.

- ISO 14644-1 and ISO 14644-3 can be referenced to establish a detailed validation framework.

Provide regular training for validation technicians

- Conduct training sessions on international standards (ISO, IEST, IPC).

- Update knowledge on new measurement methods, equipment operation, and calibration techniques.

- Ensure technicians fully understand SOPs and are capable of handling unexpected issues during validation.

Apply continuous monitoring systems

- Particle sensors: monitor 24/7 to detect abnormal increases in airborne particles.

- Differential pressure loggers: record pressure differences between rooms and trigger alerts if levels drop below 10-15 Pa.

- IoT-based environmental monitoring systems: allow for real-time data storage and quick retrieval for verification.

Regularly calibrate testing equipment

- Particle counters: must be calibrated at least once a year to maintain accuracy.

- Differential pressure gauges: should be checked and calibrated as per manufacturer recommendations.

- ESD equipment (wrist straps, chairs, flooring): resistance values must be tested and validated according to ANSI/ESD standards.

4. Frequently Asked Questions

How often should an electronics cleanroom be validated?

Typically, validation should be performed every 6-12 months. Additional validation is required after HEPA replacement, facility modifications, or when unexpected incidents occur.

Is ESD testing mandatory during cleanroom validation in electronics?

Yes. ESD control is mandatory because ESD can damage chips, ICs, and PCBs. Measuring resistance of flooring, wrist straps, and chairs should be conducted following ANSI/ESD standards.

When should HEPA/ULPA filters be revalidated?

Filters should be tested after every replacement or at least once a year. If pressure increases abnormally, airflow decreases, or leaks are suspected, DOP/PAO testing must be carried out immediately.

What are the risks of incorrect differential pressure?

If differential pressure is not maintained at 10-15 Pa minimum, cross-contamination can occur, allowing dust from less clean areas to enter critical zones. This significantly increases defect rates, especially in semiconductor and PCB production.

5. Contact now to receive support from VCR

Are you preparing for cleanroom validation in your electronics manufacturing facility for chips, PCBs, or SMT components?

Don’t let minor validation errors cause major losses to your production line.

VCR Cleanroom Equipment is ready to support you with:

- Cleanroom validation services in compliance with ISO 14644 - IPC - IEST.

- Internationally certified measuring equipment, calibrated on a regular basis.

- A team of experienced experts in electronics and semiconductor cleanrooms.

- Comprehensive checklists and validation reports, meeting QA/QC requirements and international audit standards.

Contact us today for consultation and quotation.

Hotline: 090.123.9008

Email: [email protected]

Website: https://phongsachdientu.com/

Diep VCR

Vietnam Cleanroom (VCR) là một doanh nghiệp hàng đầu tại Việt Nam chuyên cung cấp thiết bị và giải pháp phòng sạch. Với hơn 10 năm kinh nghiệm phục vụ các dự án phòng sạch đạt tiêu chuẩn GMP, VCR tự hào mang đến các thiết bị kỹ thuật cao như: đồng hồ chênh áp, khóa liên động, đèn phòng sạch, Pass Box, FFU (Fan Filter Unit), buồng cân, HEPA Box, Air Shower, cửa thép phòng sạch, tủ cách ly (ISOLATOR), và nhiều loại phụ kiện chuyên dụng khác

Không chỉ là nhà cung cấp thiết bị, VCR còn là đơn vị phân phối độc quyền các sản phẩm từ các thương hiệu quốc tế như LENGE và BLOCK Technical, đồng thời cung cấp các giải pháp phòng sạch toàn diện cho các lĩnh vực như dược phẩm, điện tử, y tế, thực phẩm và mỹ phẩm. VCR có đội ngũ chuyên gia giàu kinh nghiệm, kiến thức chuyên sâu về phòng sạch, hỗ trợ tư vấn về tiêu chuẩn, thiết kế, thi công và vận hành phòng sạch theo chuẩn ISO, GMP, HACCP, ISO 14644

VCR hướng đến trở thành thương hiệu quốc dân trong ngành phòng sạch, với mạng lưới cung ứng rộng khắp, VCR có các văn phòng tại Hà Nội, TP. HCM, đáp ứng mọi yêu cầu từ xây dựng đến nâng cấp môi trường sản xuất đạt chuẩn

Email: [email protected]

Điện thoại: (+84) 901239008

Địa chỉ:

VP Hà Nội: 9/675 Lạc Long Quân, P. Xuân La, Q. Tây Hồ, TP. Hà Nội

VP Hồ Chí Minh: 15/42 Phan Huy Ích, P.15, Q. Tân Bình, TP.HCM

Hãy liên hệ với VCR để tìm hiểu thêm về lĩnh vực phòng sạch hiệu quả nhất nhé!